CONTRACTED MACHINING

In 2010, we created a new internal machining department with the aim of eliminating even the smallest dependency from our production chain, in terms of both time and quality, which derived from the outsourcing of mechanical components.

Today, thanks to the know-how of our design department and our sophitisticated and state-of-the-art equipment, we can design and produce more quickly high-quality mechanical parts for third parties.

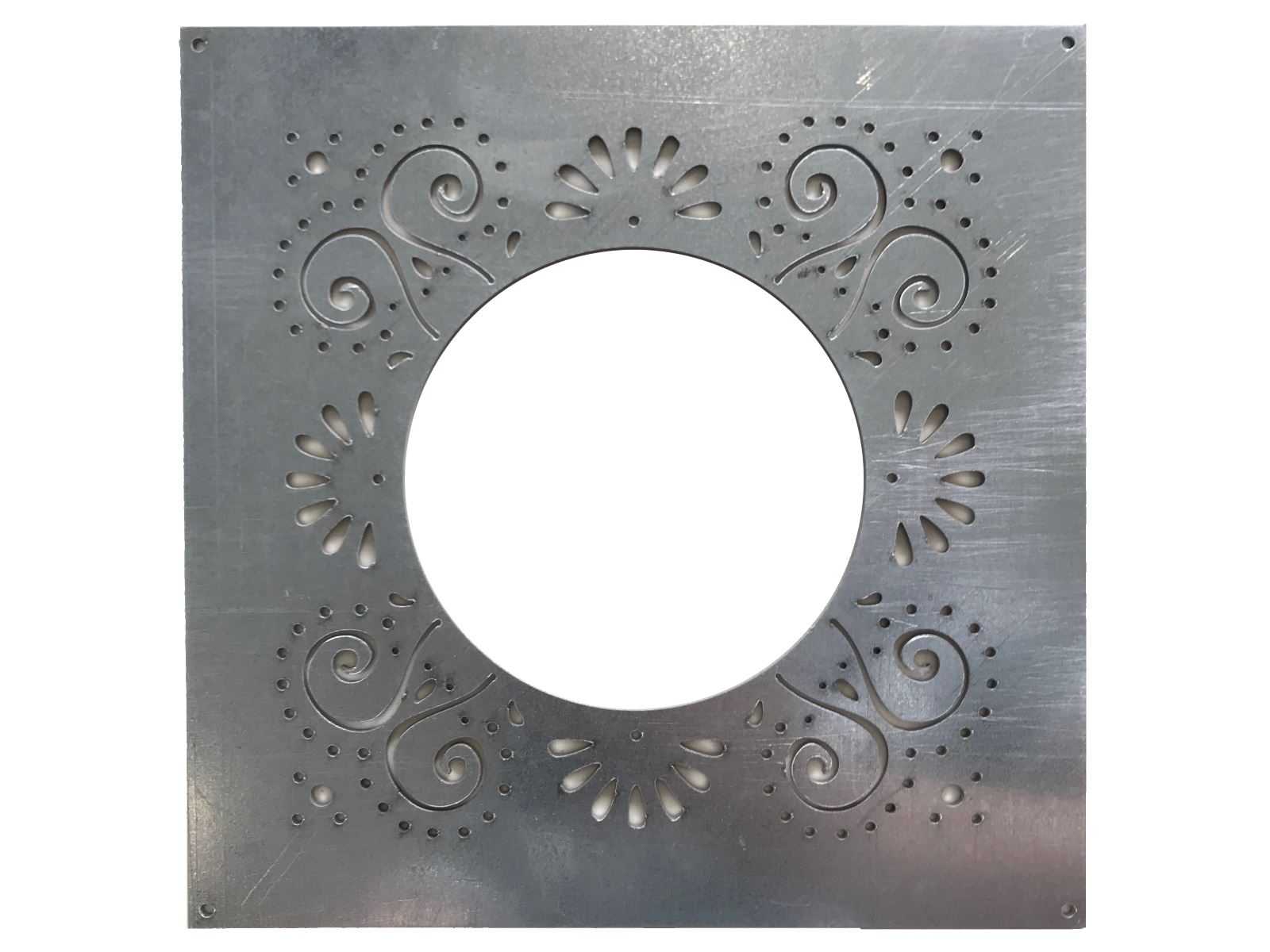

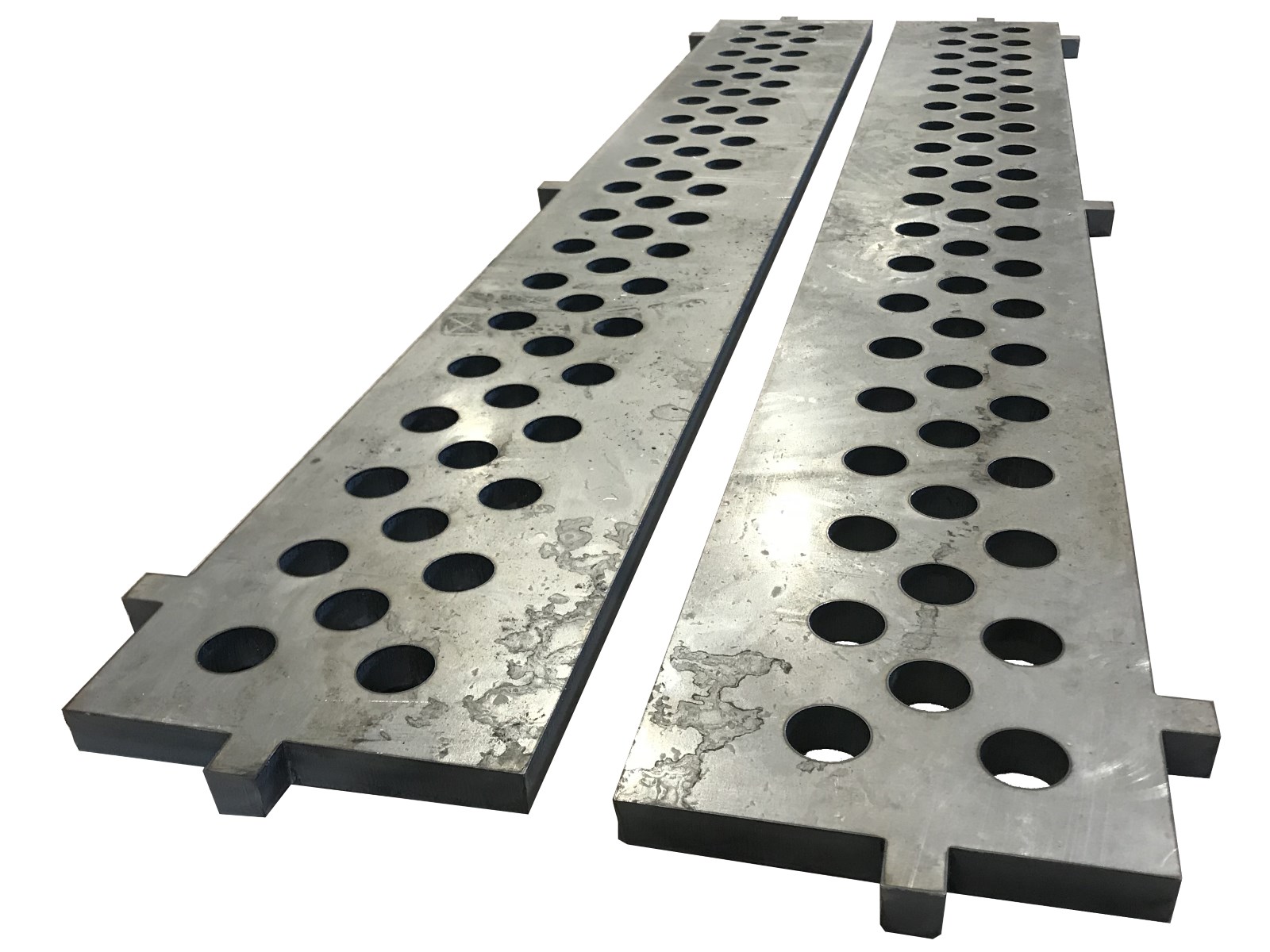

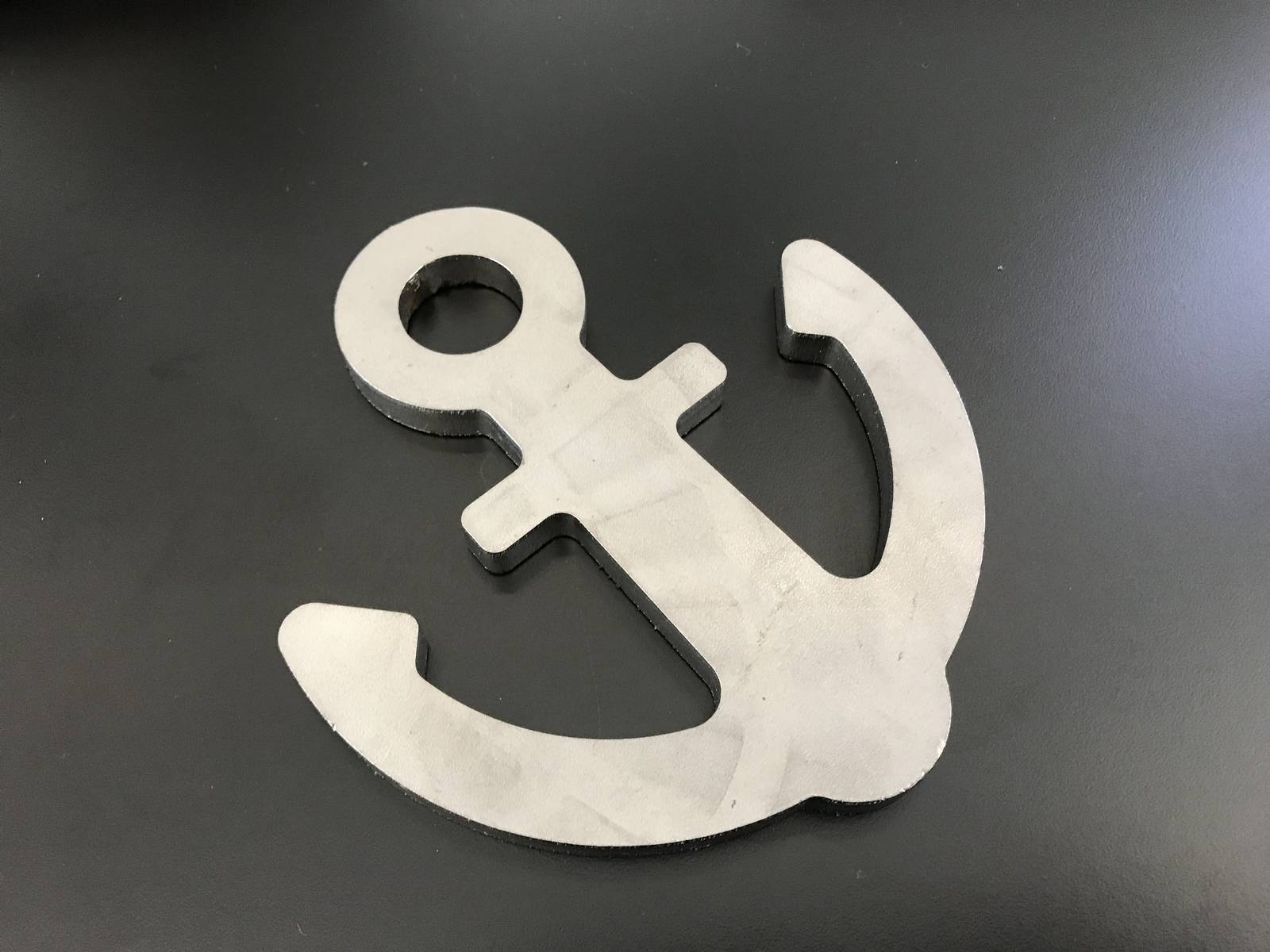

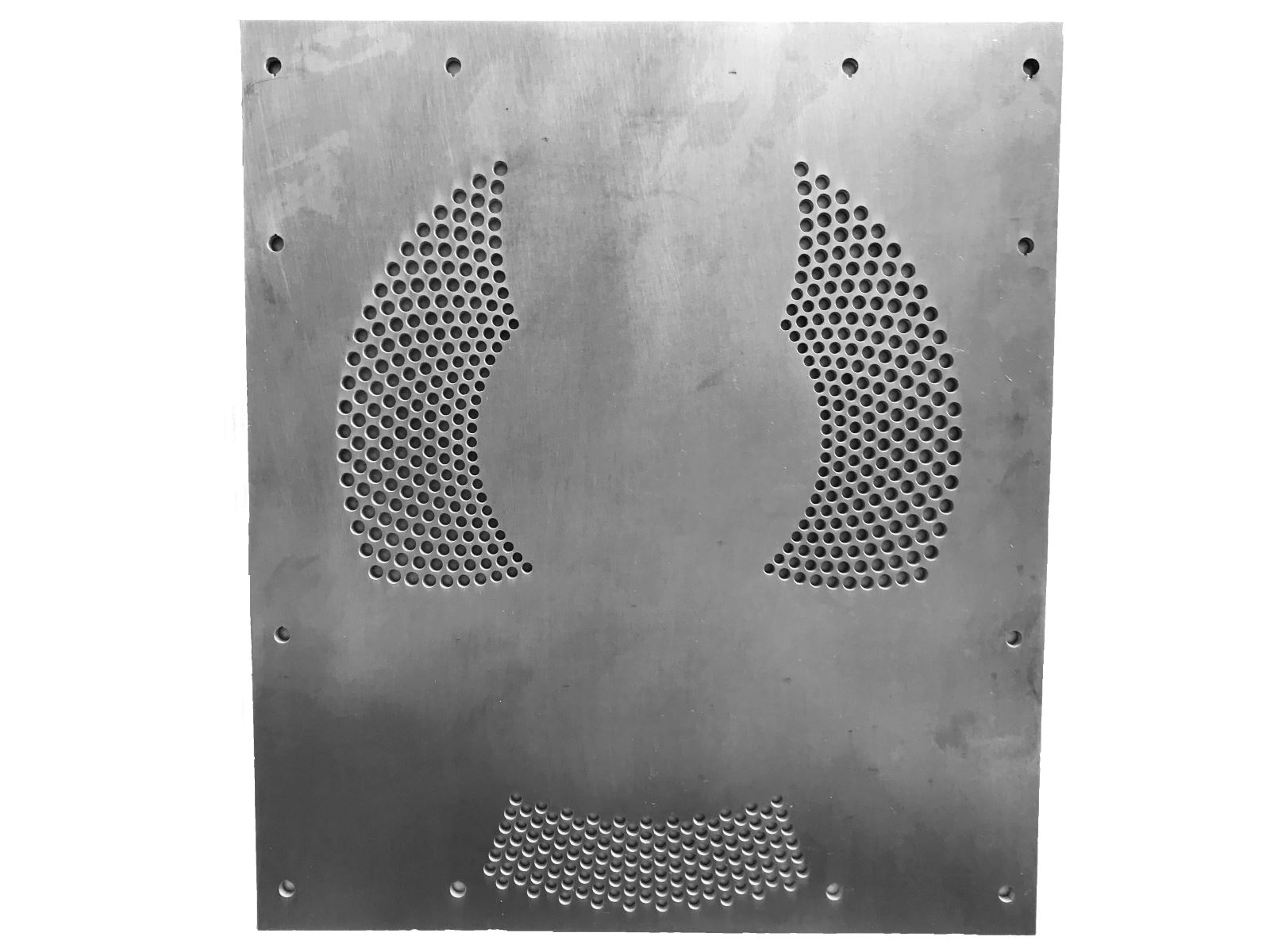

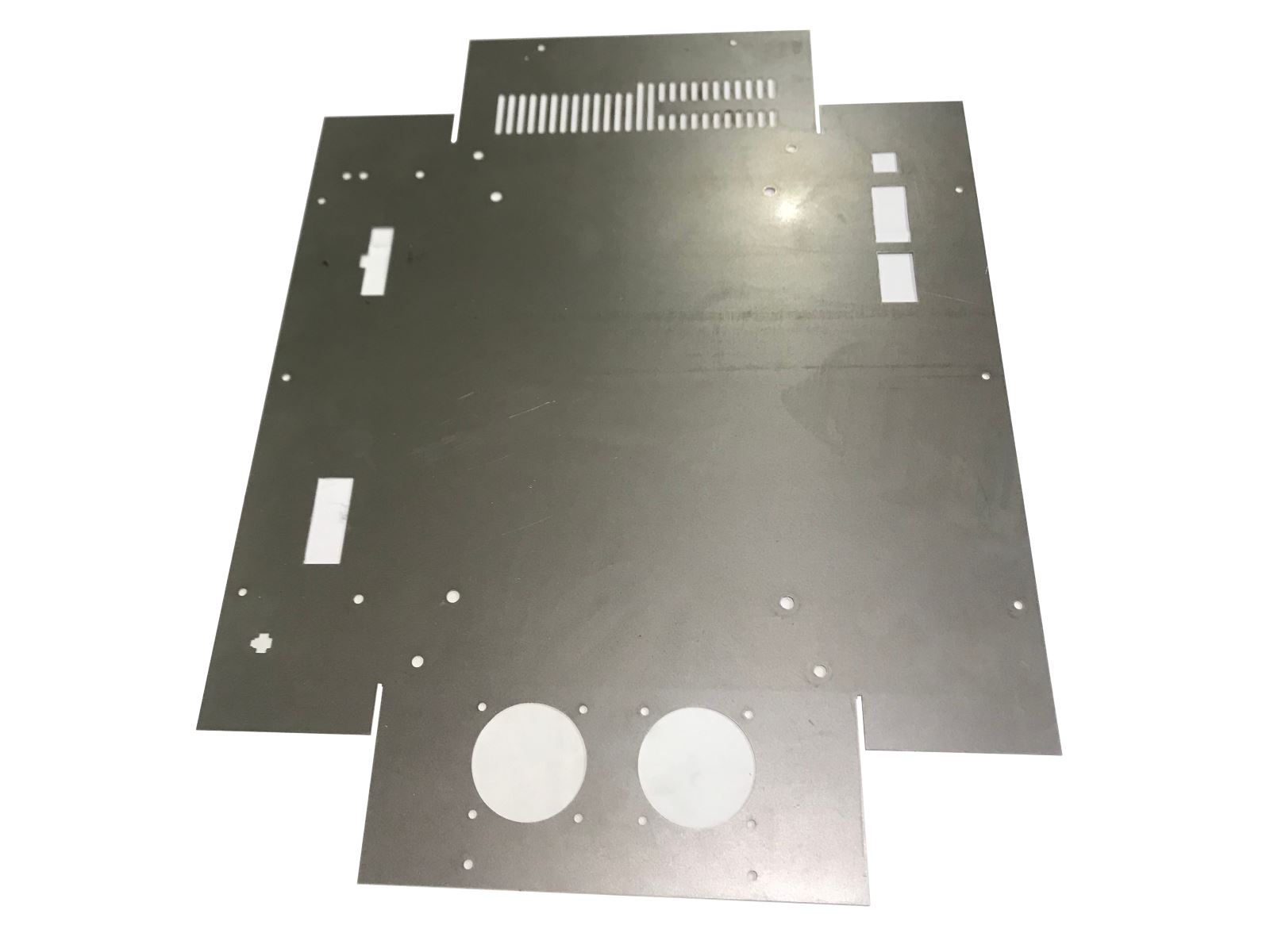

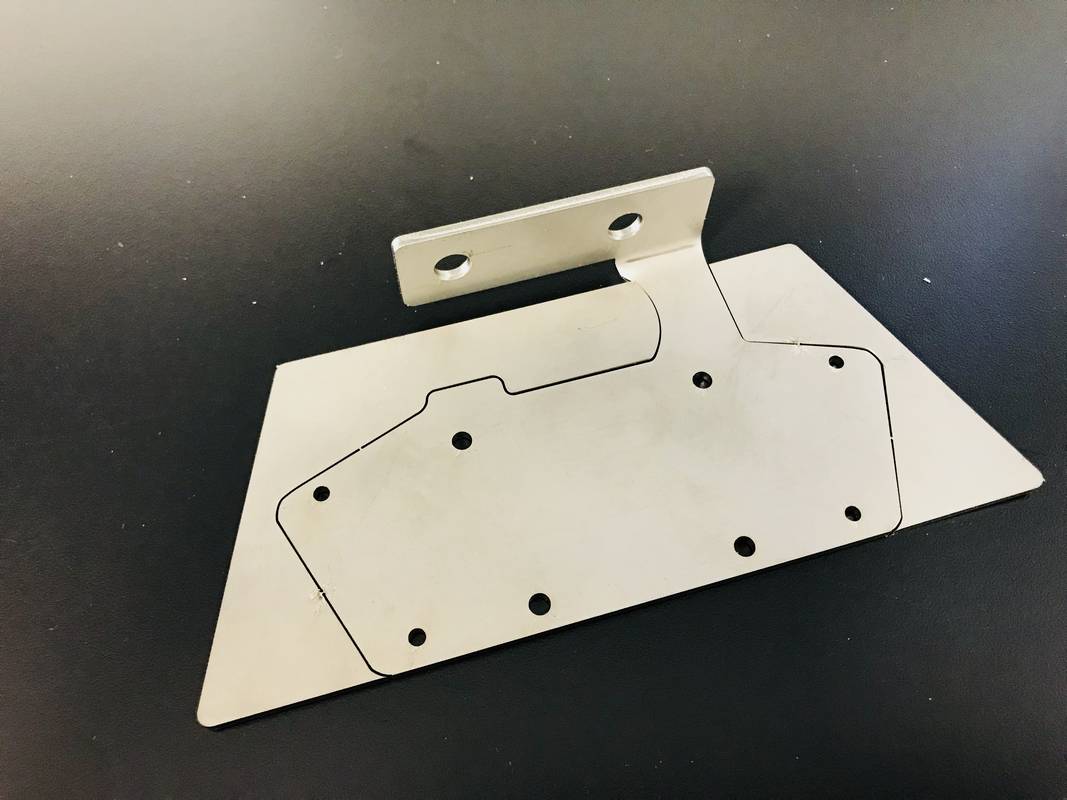

4 kW laser cutting

This allows us to use materials that cannot be cut by a CO2 laser and with improved energy efficiency

Fitted with high-acceleration linear motors with precision down to two decimal places, it can machine sheets of up to 3.0 X 1.5 m with thicknesses of up to 22 mm in iron and 15 mm in stainless steel or aluminium.

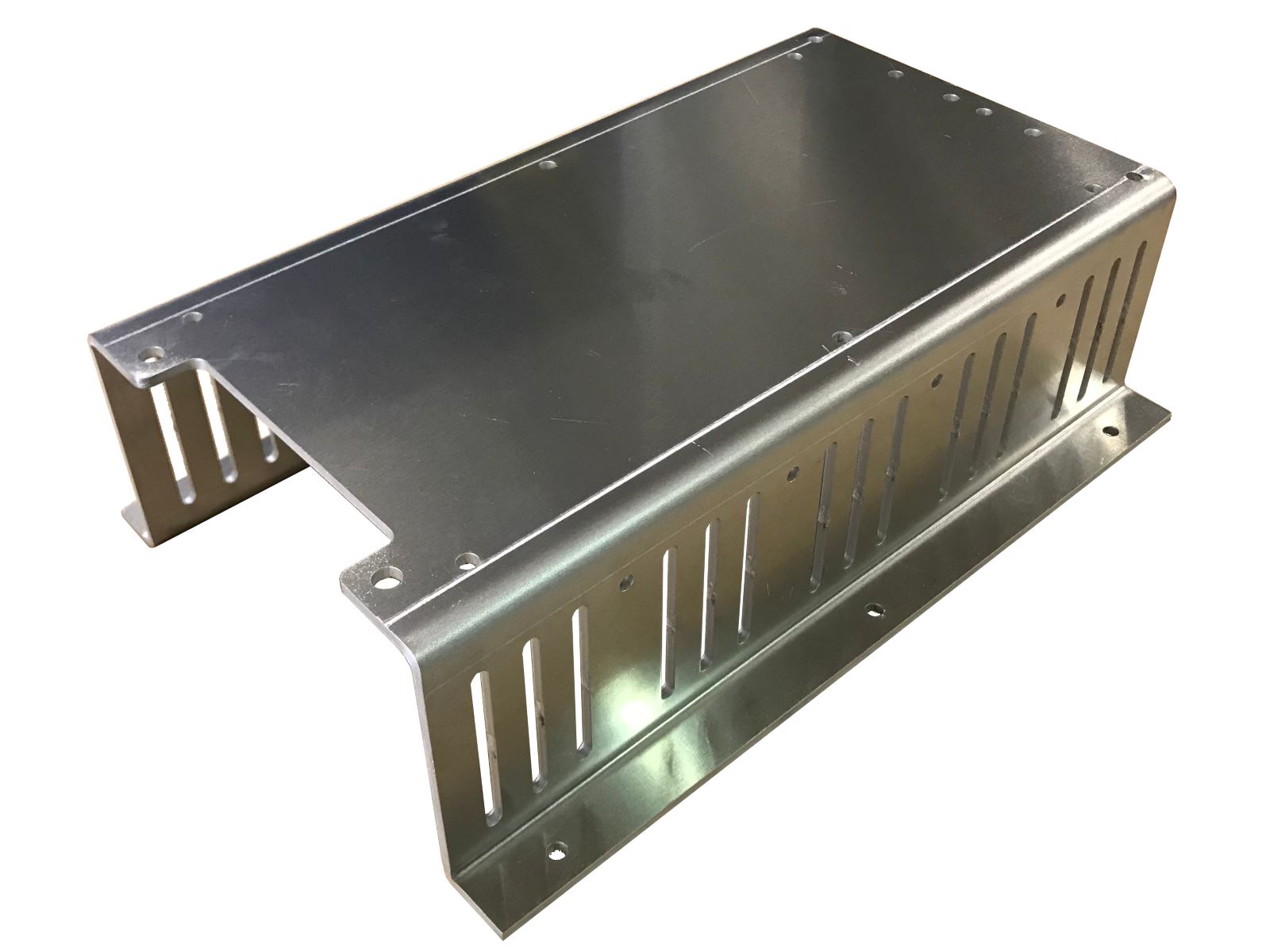

Mechanical bending

The bending production process is used to bend metal sheets into the desired shape.

We perform contracted machining with robotic and manual bending to guarantee maxiumum quality.

Production of "custom sized" mechanical parts even in small quantities.

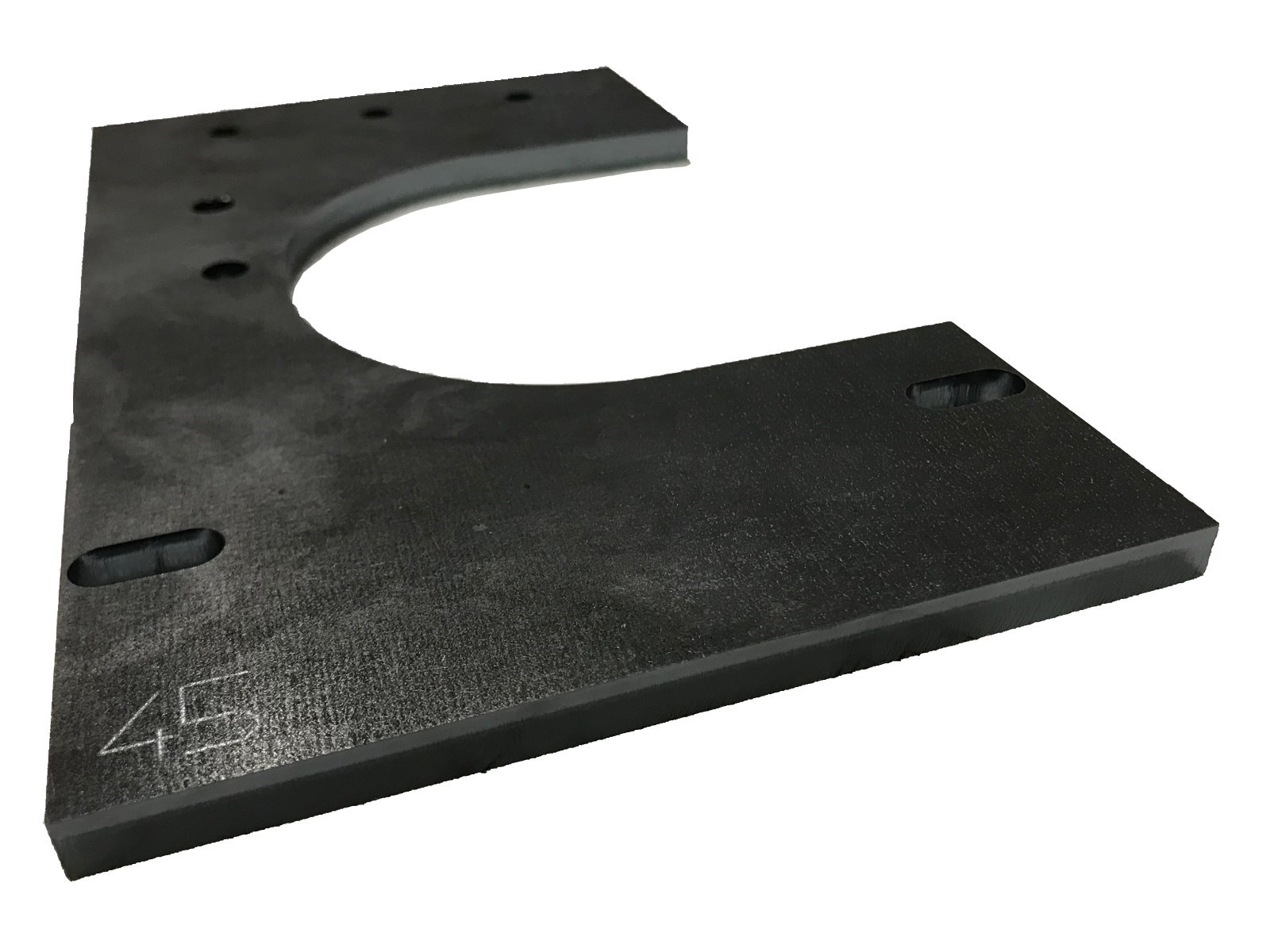

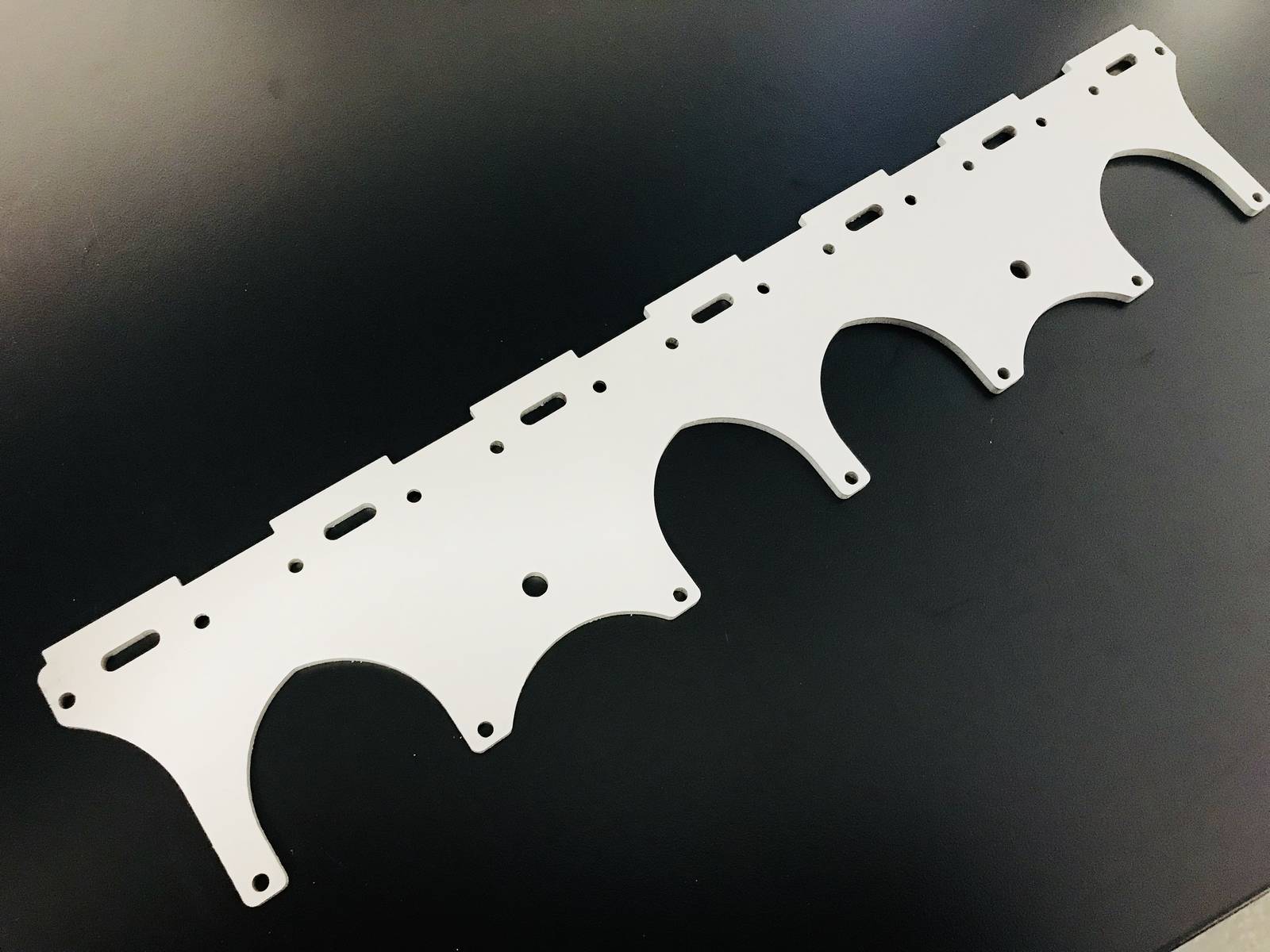

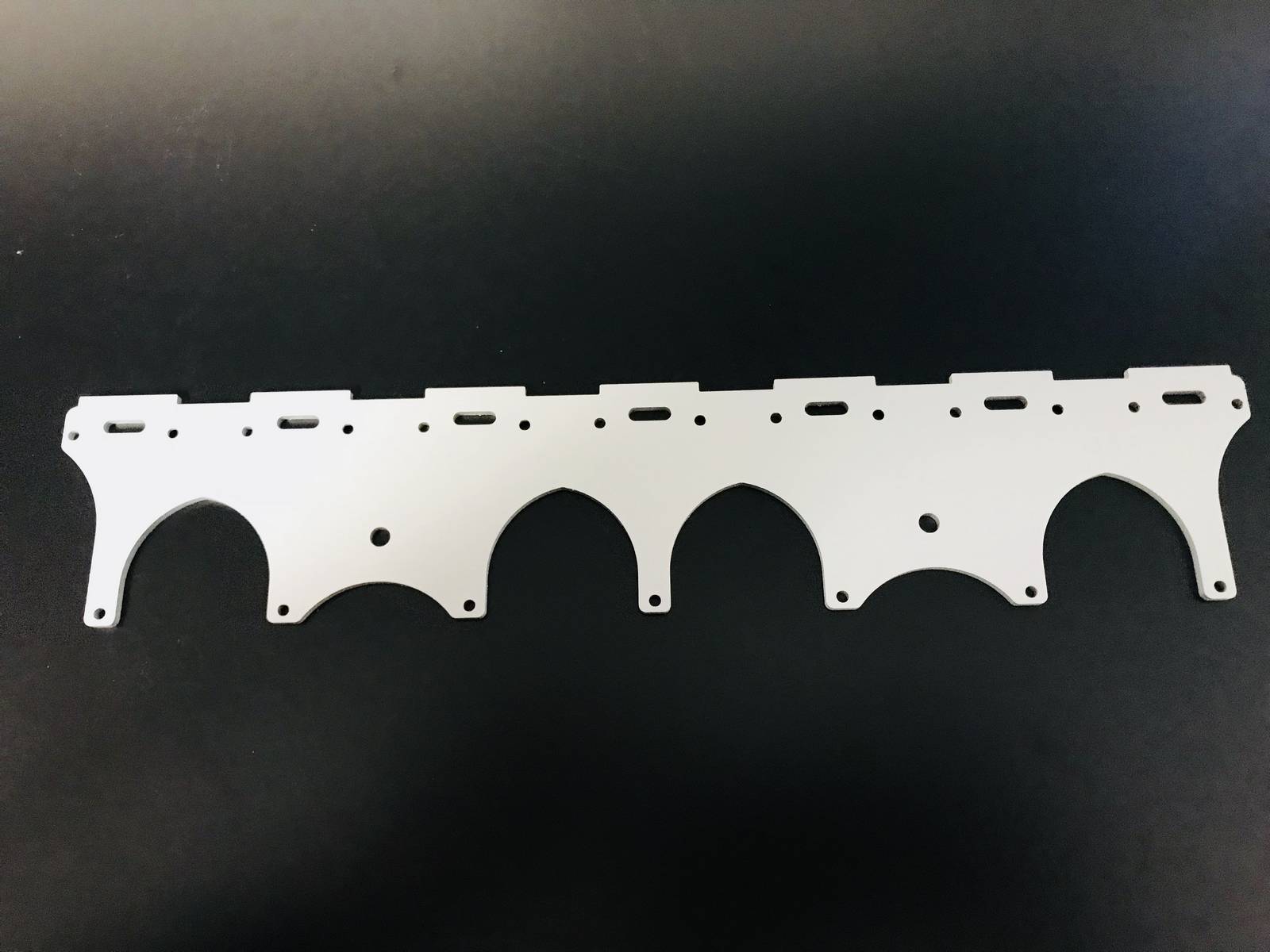

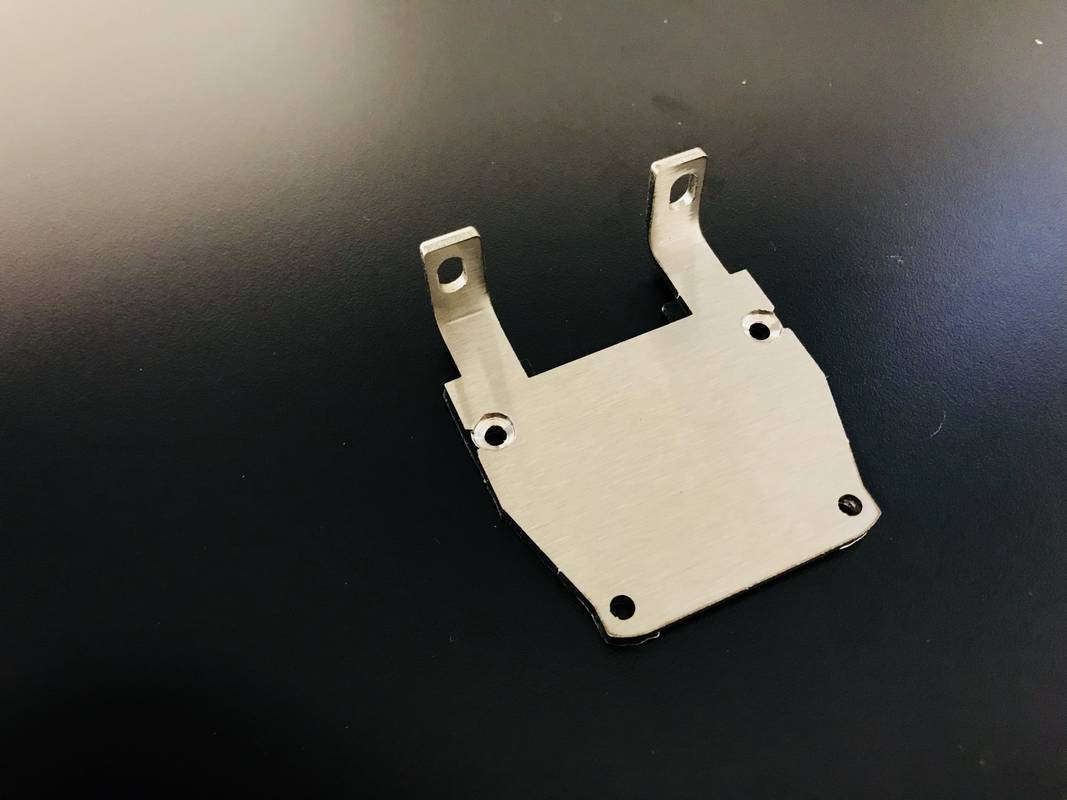

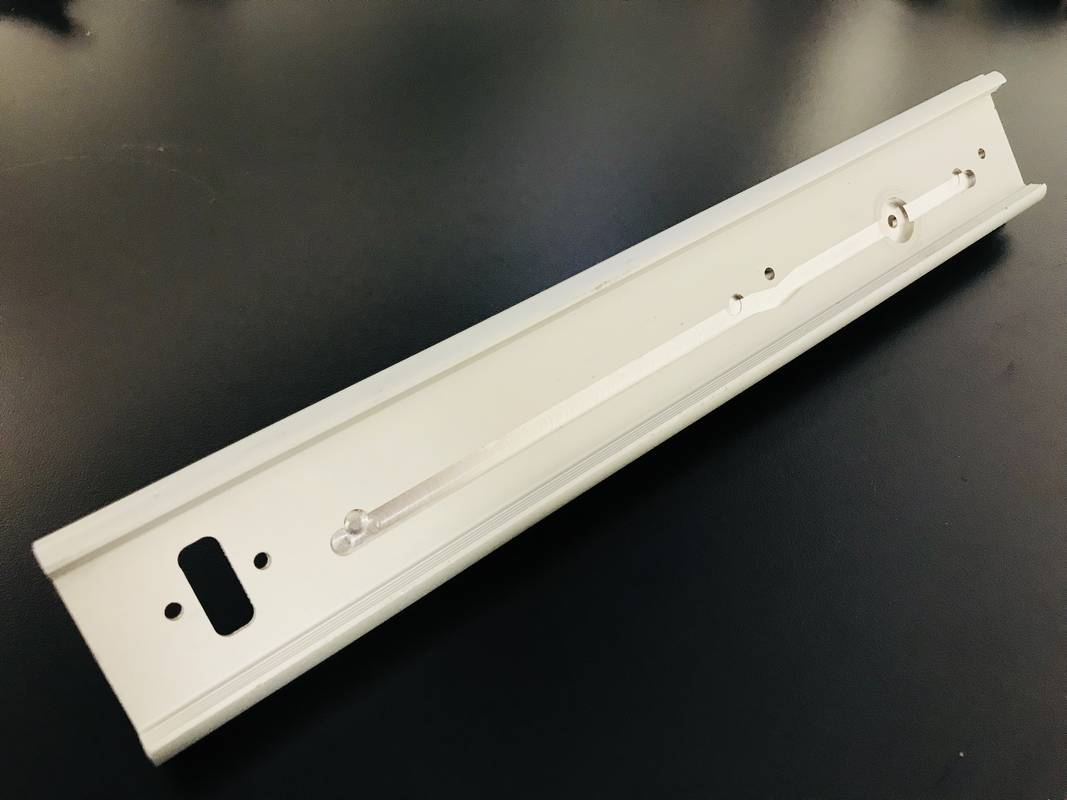

CNC Machining Centres

5-axis CNC machining centres capable of fulfiling every customer requirement.

Starting with the design, Lomar manages every single stage of production.

Thanks to our inventory of cutting-edge machines, we are able to undertake the contracted machining of mechanical parts in minimum time and with maximum efficiency.

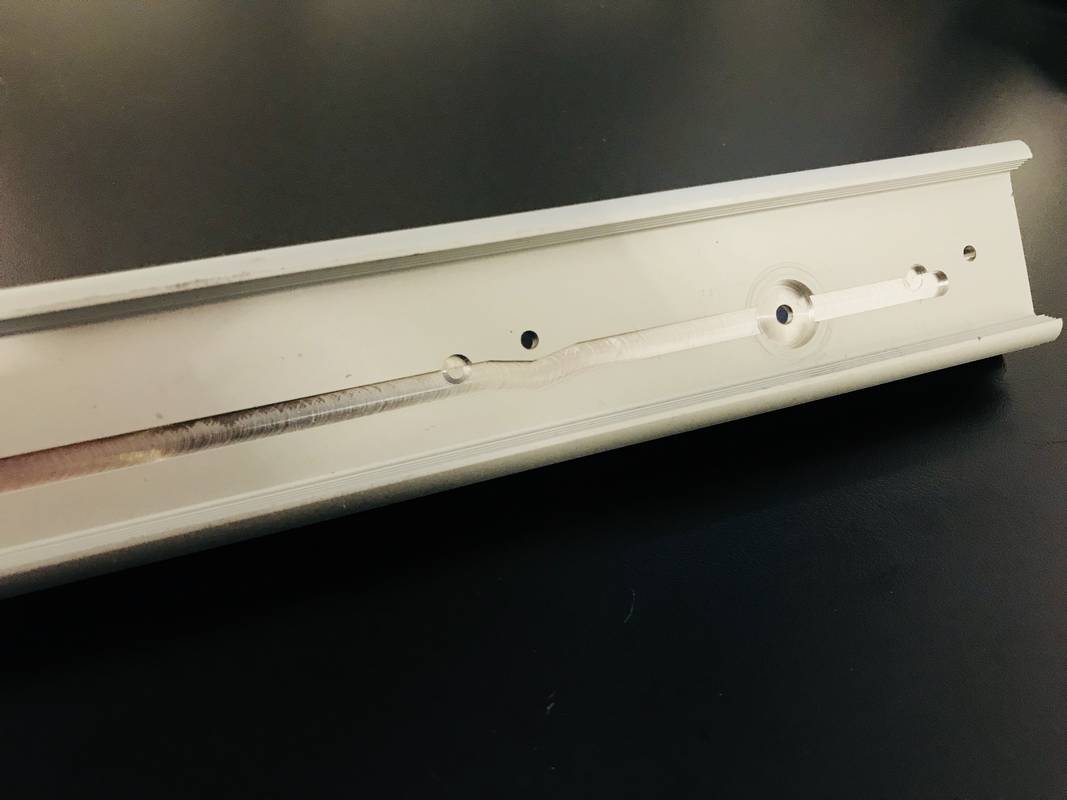

TIG welding

TIG (Tungsten Inert Gas) welding produces high quality joints

The TIG process is particularly suited to welding thin materials, right down to a few tenths of a mm.

For high standard operation, it requires qualified, expert operators who are able to perform welding that doesn't break easily and is free from burrs and residue.

Lathe

Turning is the most common chip removal machining that consists of obtaining "turning" parts, i.e. parts symmetrical in relation to a central axis of rotation.

Thanks to our manual control parallel lathe, Lomar is able to create threaded pieces and mechanical parts of varying size and with high quality finish, to meet every demand of our customers, even in short runs.